Validation of Acoustical Performance Testing

USG Corporation, an industry-leading manufacturer of building products and innovative solutions, engaged an acoustic testing facility for testing of its gypsum products in a variety of construction systems. Manufacturers of construction and building materials regularly test their products for acoustical performance in walls, floor-ceiling assemblies, roof systems, etc. Building codes and design standards specify minimum acoustical requirements for these construction systems and assemblies, so accurate testing is vital.

Challenge

USG conducted airborne sound transmission loss testing of partition systems containing its gypsum products. Testing was conducted in an accredited acoustical laboratory per the ASTM E90 Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements. Sound was generated on one side of the test partition and sound levels were measured on both sides of the partition to determine how much noise was blocked by the specimen. However, the measured performance was lower than anticipated and anomalies in the resulting data indicated potential issues with the installation of the specimen. Visual inspection of the test partition did not immediately identify any issues or sound flanking paths.

Solution

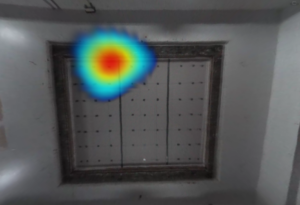

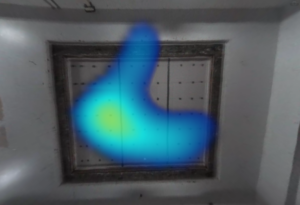

VisiSonics 5/64 Audio Visual Camera allows for acoustic visualization, making detecting the source of sound and leaks much easier. Like a heatmap, the Audio Visual Camera provides “hot spots” on a visual panorama to highlight the location and pressure level of sounds. Using both video cameras and microphones along with software, the VisiSonics solution simultaneously generates a synchronized and co-registered audio and video view of the captured environment. The camera output allowed USG engineers and the testing facility team to isolate where sounds were coming from and determine that airborne sound was leaking around the test partition.

“The VisiSonics Audio Visual camera allowed us to find airborne sound leaks around the test partition that were not apparent during visual inspection. After sealing these sound flanking paths, we achieved a more accurate measure of the test partition with higher STC results. The VisiSonics technology let us visualize sound in a way we couldn’t otherwise.”

Andrew Schmidt, Senior Researcher, Acoustics – USG

Result

VisiSonics camera and accompanying software allowed the USG engineers to see airborne sound leaks around the test partition, which helped to explain the unexpected results during initial testing. In this way, the flanking paths and leaking noise were mitigated prior to the final validation testing. This resulted in a more accurate measure of the sound passing through the test partition and a more accurate and improved STC rating for the USG assembly.

Sound flanking identified: Air leak through perimeter

+3 STC in measurement after flanking path was mitigated

Contact VisiSonics for this and other applications where accurate acoustic measurements are necessary for noise mitigation.